Precision Tooling and Tool Making Services.

Exceptional Tooling Solutions for Plastic Injection Moulding

At Budtec, our expertise in tooling and tool making is the foundation of our high-quality plastic injection moulding services. We understand that the precision and durability of your moulds directly impact the quality and efficiency of your production. Here’s how we deliver exceptional tooling solutions tailored to your needs:

Expert Tool Design

- Customised Designs: Our tooling design process starts with understanding your specific requirements. We create custom designs that ensure optimal performance and longevity of your injection molds.

- Advanced Technology: Leveraging the latest CAD/CAM software, our engineers produce detailed and precise mould designs. These designs are optimised for manufacturability, ensuring efficient production and high-quality end products.

- Innovative Solutions: We stay ahead of industry trends and incorporate innovative solutions into our designs. Our team anticipates potential challenges and addresses them early in the design phase, saving you time and costs.

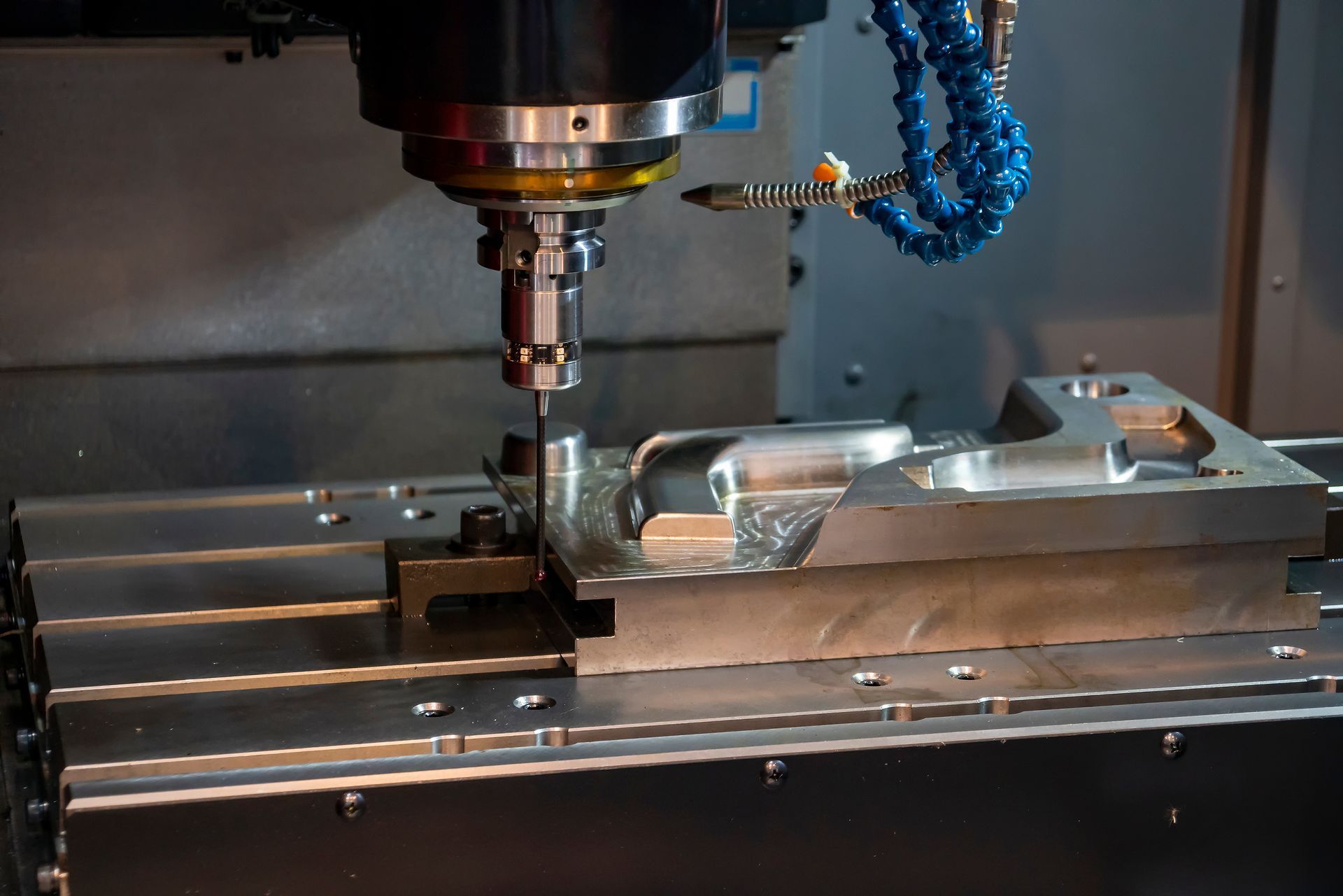

Precision Tool Making

- State-of-the-Art Equipment: Our tool making facility is equipped with advanced machinery, including high-precision CNC machines, EDM equipment, and grinding machines. This technology enables us to create molds with exceptional accuracy and intricate details.

- Skilled Craftsmen: Our team of experienced tool makers brings a wealth of knowledge and skill to every project. They meticulously craft each mold, ensuring it meets our stringent quality standards and your specific requirements.

- Material Selection: We use high-quality materials to manufacture durable and reliable molds. Our selection process ensures that the materials chosen are best suited for your product’s specifications and production volume.

Comprehensive Tooling Services

- Prototyping and Testing: Before full-scale production, we create prototype moulds to validate the design and functionality. This step allows for any necessary adjustments, ensuring the final mould performs flawlessly.

- Maintenance and Repair: To extend the life of your moulds, we offer comprehensive maintenance and repair services. Regular maintenance keeps your molds in peak condition, while our repair services quickly address any issues, minimising downtime.

- Lifecycle Management: We manage the entire lifecycle of your tooling, from initial design through to production and maintenance. Our holistic approach ensures consistency, reliability, and cost-efficiency throughout the life of your project.

Quality Assurance

- Rigorous Inspections: Quality is paramount in our tooling process. We conduct rigorous inspections at every stage of tool making, using advanced measuring equipment to ensure every moold meets exact specifications.

- Customer Satisfaction: Our commitment to quality and precision ensures that your moulds produce high-quality parts consistently. We aim to exceed your expectations with every project, building lasting partnerships based on trust and excellence.

Why Choose Budtec for Tooling and Tool Making?

- Experience and Expertise: With years of experience in the industry, we bring unparalleled expertise to your tooling projects. Our team is dedicated to delivering innovative and reliable solutions.

- Tailored Solutions: We understand that every project is unique. Our customized approach ensures that we meet your specific needs and help you achieve your production goals.

- Advanced Technology: By investing in the latest technology and equipment, we ensure that our tooling solutions are at the forefront of industry standards.

Start Your Tooling Project with Us

Whether you need a new mould or maintenance for an existing one, [Your Company Name] is your trusted partner for precision tooling and tool making. Contact us today to discuss your project and discover how we can enhance your production capabilities with our expert services.

Interested in our services? We’re here to help!

For an informed discussion about Budtec's range of services, please contact us via phone during business hours on

0433 626 699, alternatively use the contact form on the website to lodge an enquiry.